how to test friction piles|friction pile formula : manufacture The final result of this work was an Excel file for calculating friction piles with two different types of soil and two different methods of design: empirical calculation and results of site investigations. This file allows to check the designed foundation for compliance with the main criteria. WEB30,031 baixinha dando o cu FREE videos found on XVIDEOS for this search.

{plog:ftitle_list}

Resultado da 2 dias atrás · Epsódios: Aninha pega carona para ir à faculdade, mas está doida pra fugir dos deveres! Sem calcinha, ela provoca Sr. Carlos durante .

The final result of this work was an Excel file for calculating friction piles with two different types of soil and two different methods of design: empirical calculation and results of site investigations. This file allows to check the designed foundation for compliance with the main criteria. Pile testing is especially important as the majority of the pile is imbedded into the founding soil making visual inspection impossible. Therefore different types of pile testing is employed to verify a piles integrity and strength .This chapter concentrates on vertical load tests on piles. However, most of the recommendations in this chapter are equally valid for load tests on raking piles, tension piles and for the lateral .Pile load testing methods are critical for validating the design assumptions made for friction piles before full-scale implementation. Both static and dynamic load tests provide insight into how .

This article will provide an overview of friction piles, discuss their advantages and limitations, and explain best practices for engineers considering using them in their next project. Friction pile gets its name from the method used to transfer .To calculate the capacity of a friction pile one has to multiply the pile surface area to the safe friction force developed per unit area. The skin friction to be developed at a pile surface should be evaluated sincerely and a reasonable . As an alternative to, or in conjunction with, static load testing, we have equipment that can determine the ultimate pile capacity and details of the support mechanism for driven piles. The equipment is called a Pile Driving .PILE LOAD TEST INSTRUMENTATION An expanding requirement to build on difficult terrain has seen an increase in the use of piles for support of buildings and infrastructure, and a growing .

Load Test on Friction Piles in Clay. Authors. U. Bergdahl; G. Hult. Published In. 10th International Conference on Soil Mechanics and Foundation Engineering (Stockholm) Theme. . We can obtain the pile skin friction and end bearing developed to the test load. Initially, the pile testing will be simulated with software and the falling height of the hammer is decided in such a manner that it will not .

what is a friction pile

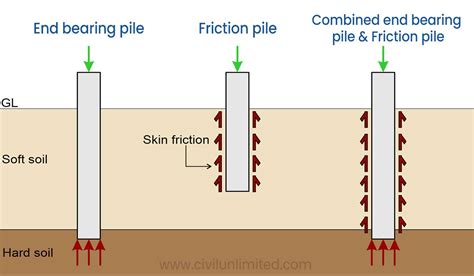

Mostly, the friction piles are precast concrete piles when they are driven into shallower depths up to about 20m. Increase the depth to the hard soil strata, cast-in-situ piles are constructed as the friction pile. In some locations, the depth .Friction Pile. Friction pile is a kind of pile foundation. This type of pile utilizes the frictional resistance force between the pile surface and adjacent soil to transfer the superstructure load. Depending on the subsoil strata condition, .Load Transfer Mechanism for Piles. Consider a loaded pile with length L and diameter D, as shown in Figure 2. The load Q on the pile shall be resisted mainly by the soil at the bottom of the pile Q p., and partly by skin friction developed along the shaft Q s.. Generally, the ultimate load-carrying capacity (Qu) of a pile can be represented by the sum of the load resisted at the tip of .End-bearing piles; Friction piles; End-bearing piles distribute the largest portion of the vertical load to the toe of the pile. They operate in the same manner as a pillar of a structure. On the contrary, the bearing capacity of friction piles derives from shear stresses that develop at the sides of the pile.

End bearing piles; Friction bearing piles; Combination of end bearing and friction bearing piles. 1. End Bearing Pile Foundation End bearing piles also called as point-bearing piles are selected when the depth of hard soil strata or bedrock at site is within reasonable depth. Proper approximation of friction capacity (FC) of driven piles is a noticeable issue in geotechnical engineering. Hence, the pivotal focus of the current research is on proposing reliable predictors for evaluating this parameter. Three artificial neural networks (ANNs) improved by firefly algorithm (FA), multi-tracker optimization algorithm (MTOA), and black hole algorithm .

4.4 Negative Friction 6 4.5 Pile Load Tests 6 4.5.1 Design capacity by load tests 6 4.5.2 Dynamic testing 6 . 8.15 Bent, Dog-Legged, or Collapsed Piles 18 8.16 Pile Installation and Testing Records 18 8.17 Probe Piles 18 9 APPLICABLE STANDARDS 18 9.1 ASTM Standards 18 9.2 AWPA Standards 20 9.3 ACI Standards 20 Of course, in cases of soil settlement, negative skin friction arise, which will lead to reduced capacity of friction piles. Friction piles are useful when the strong strata are very deep and it is becoming economically unfeasible to have end-bearing piles. In such cases, friction piles can effectively perform the function by resisting the . Total ultimate capacity of the pile = total skin friction + end bearing = 54,290 + 17,115 = 71,405 lbs (317.6 kN) Conclusion. The critical depth for skin friction in piles is a crucial parameter for the design of piles in sand. It is believed to depend on factors such as soil type, pile diameter, and installation techniques.

an MPM test. Characteristic total pile compressive resistance Rc;k or the base and shaft resistances Rb;k and Rs;k may be determined directly by applying correlation factors ξ3 and ξ4 to the set of pile resistances calculated from the test profiles. This procedure is referred to as the Model Pile procedure by Frank et al. (2004) to determine . Generally, piles are socketing depth around the diameter of the pile unless it is specified in the geotechnical report. Geotechnical capacity of pile = End Bearing Capacity + Skin Friction Capacity. The geotechnical capacity of the pile is compared with the structural capacity of the pile to obtain the load-carrying capacity of the pile.2.1.1.1.3. H-Piles as Friction Piles. While many meters of H-piles have been driven for friction applications, they are non-displacement piles and tend to drive further in loose sands and silty sand. There may be good reasons however to select H-piles for this use if, for example, a significant scour depth is computed for a bridge pier abutment.

This provides a better judgment of the actual static pile capacity measured during the field dynamic load test on piles and the friction and end-bearing components. A good match is obtained when match quality is less than five tor bored piles. However, there may be exceptions that shall be acceptable when justifiable.To determine the length of precast friction piles to avoid splices. . Test piles must be installed plumb and to the specified tip elevation shown on the contract plans. All the piles (anchor and test piles) in each test group need to be .

soil friction piles

Especially in the case of embedded piles, reducing a pile’s length in the calculation can cause the shaft friction of the embedded pile to be neglected, and the calculated resistance of the pile .

The founding depth of the pile is influenced by the results of the site investigate on and soil test. Friction or cohesion piles Carrying capacity is derived mainly from the adhesion or friction of the soil in contact with the shaft of the pile .

Load Test on Friction Piles in Clay Authors U. Bergdahl; G. Hult Published In. 10th International Conference on Soil Mechanics and Foundation Engineering (Stockholm) Theme. Pile Foundations. Categories Pile Foundations, Site Characterization & In-situ Testing (General) Download PDF. International Society for Soil Mechanics and Geotechnical . As friction piles, H-piles tend to drive further in loose sands and silty sand. When H-piles are driven into stiff clays, the soil is usually trapped between the flange and the web, and becomes compacted. . If the test results show that either the soil or the water are outside of the safe range for aluminum, then protected aluminum, non .7.0 LOAD TEST 30 - 33 8.0 THE HILEY FORMULA 34 - 39. Unit Kej. Geoteknik, CPKA, JKR Malaysia 11.7.2017 2 1. 0 INTRODUCTION. . - negative friction or pile in settling ground 3. 0 CLASSIFICATION OF PILE Classification of pile is a useful tool .Friction pile: When the pile is heated, the top half section moves upwards, whereas the bottom half section moves downwards as shown in Fig. 7.12.If the two ends are free to move (ie, the bottom end is soft and the building founded by energy pile group is free to move as a rigid body), the strains at these two locations are equal to αΔT.The largest restraint is located at the .

For bored cast-in-situ piles measuring up to 31 m in length, negative skin friction force calculations are compared according to static load test and accompanying cone penetration testing (CPT) data in subsiding soils. The negative skin friction forces calculated on the basis of CPT data are shown to be the closest to those obtained in static pile tests, taking the CPT .

equal to the number of piles times the ultimate bearing capacity. For piles which rely on skin friction in a deep bed of cohesive material, the ultimate bearing capacity of a large group maybe substantially less than the number of piles times the ultimate bearing capacity. 6-2. Driving. a. Effects on the soil. When piles areinfluenced by the results of the site investigate on and soil test. 1.4.3 Friction or cohesion piles Carrying capacity is derived mainly from the adhesion or friction of the soil in contact with the shaft of the pile (see fig 1.2). Figure 1-1 End bearing piles Figure 1-2 Friction or cohesion pile 1.4.4 Cohesion piles Figure 1 gives the relationship between α and c u based on pull out test results as collected by Sowa (1970). As per Sowa (1970), the values of c a agree reasonably well with the values for piles subjected to compression loadings.. Uplift capacity of pile in sand. The ultimate uplift capacity of a vertical pile for piles embedded in sandy soil depends on the skin .

the test pile performance to be monitored throughout the full duration of the test. 2.3 Load application limits • The maximum test load to be applied must be agreed in advance so that the test pile, pile cap (if required) and the load testing equipment (reaction piles/kentledge/ hydraulic ram and pump/bi-directional load cell/rapid or dynamic .During the driving of the pile, the hard soil available at the upper part move downwards and results in the change of pile side friction. Again, water film or dense mud film is developed between the pile and surrounding soil as the pile jacking frequency increases. . The heating leads to a relative displacement between the test pile and soil .

pile testing in construction

pile strength testing methods

WEBTons of free Facesitting porn videos and XXX movies are waiting for you on Redtube. Find the best Facesitting videos right here and discover why our sex tube is visited by .

how to test friction piles|friction pile formula